Operational Guide CNC Milling Machine:

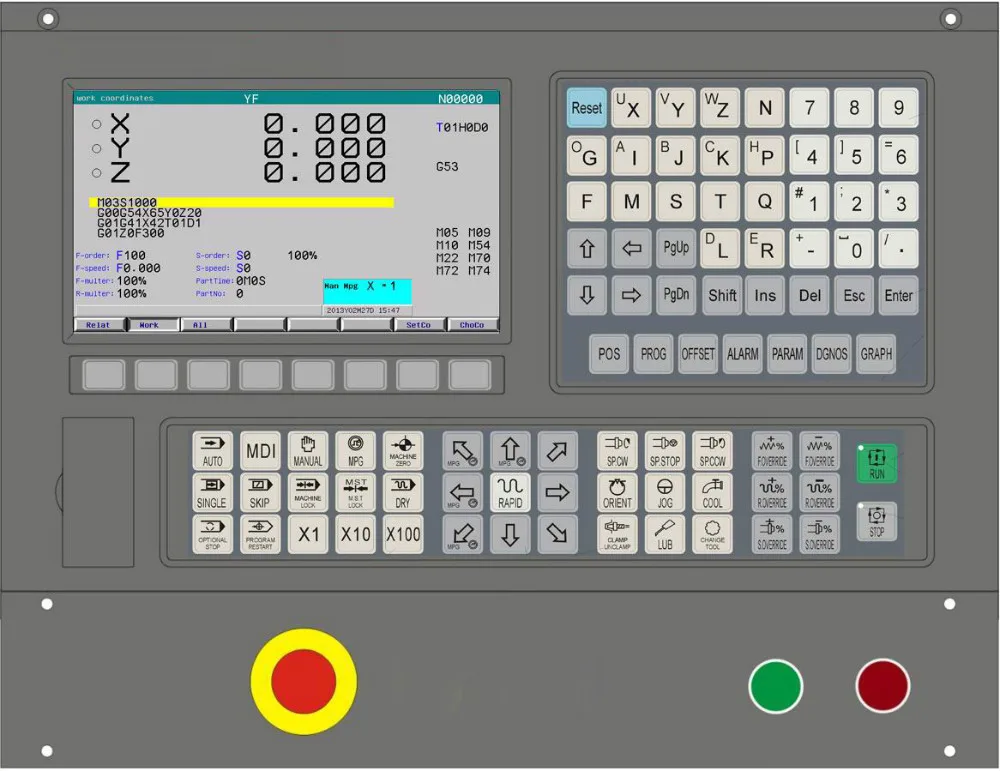

- For B-type secondary panel, we only install “Emergency Stop” “Run” “Stop” three buttons and left 4 holes, but this price will add MPG on the board and provide the MPG thread as well.

- For our 330 CNC Control Series, it can combine with motor with absolute encoder; if the need to match with driver and absolute engine, please check with us.

CNC control for Milling and Engraving Machine-GREAT-330iM:

> axes control: 3 axes

> Axis linkage: 2-3 axes

> 32 bit 400 MHz-600 MHz Industrial ARM processor

> 100 MB user memory

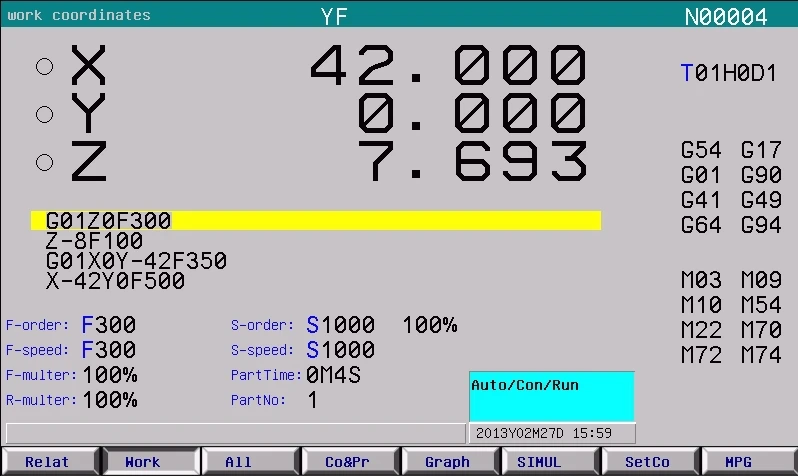

> resolution 800×480, 8 “TFT color LED displayer

> Max rapid cross-pieces: 20 m / min

> Max cutting speed: 10 m / min

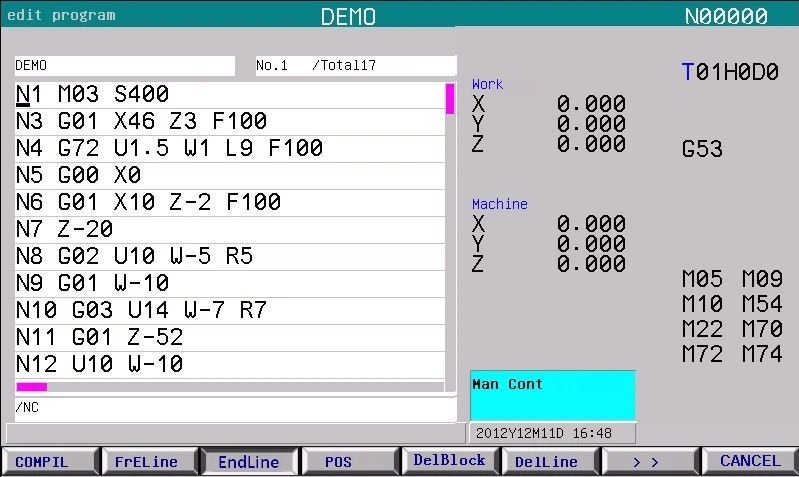

> program preview function

> USB, RS232 port for DNC function

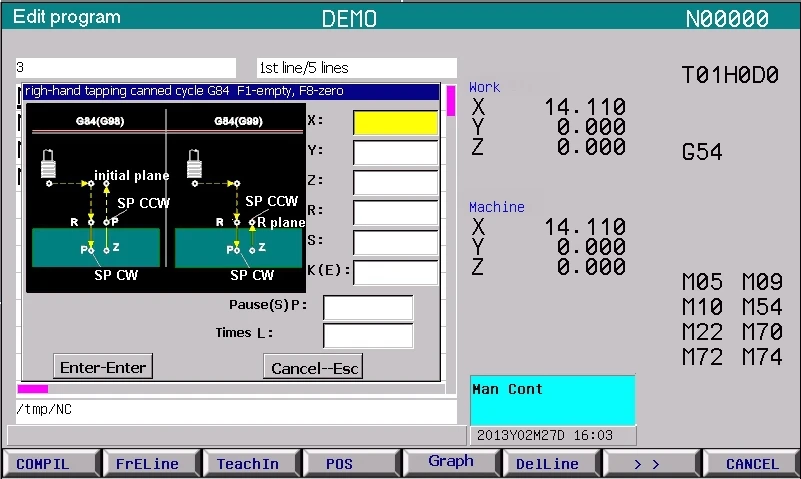

> 2D / 3D graphical preview or operation simulation before machining

> multiple level password protection, such as program, parameter or convenient protection equipment management

> start random machining block number or tool

> graphics dialog function

>real-time and all-round self-diagnosis function

> Feed per minute, feed per revolution

> metric system, input mode of the English system

> machine return to reference / variable zero

> linear, arc, helix interpolation, drilling, boring, touching etc.

> Multiple macro in loop box, macro instructions for direct interpolation and surface grinding of the rotating body

> automatic compensation and compensation of stock step error, automatic tool length compensation, tool radius compensation, internal and external transition, automatic tip angle

> set the maximum speed and up / down speed of each axis independently

> scaling, rotation coordinate system and mirror function

> move between British metric / program units

> adjustment of the axis auxiliary angle and shift programs setting

> multiple setting coordinate system

> soft and hard limit function for max stroke

> English / Chinese language selection

> current display time, single piece and execution time

> multiple interpolation function and MS T function

> parameter, full backup and software update function

Reviews

Clear filtersThere are no reviews yet.